D049

Details

Releasing a complex glass piece from the mould is the main issue of any moulding technique. In kiln casting, often very big efforts are implied in building a lost wax mould which then would last for one firing only.

This project aimed to explore a new and flexible way to construct a temporary mould.

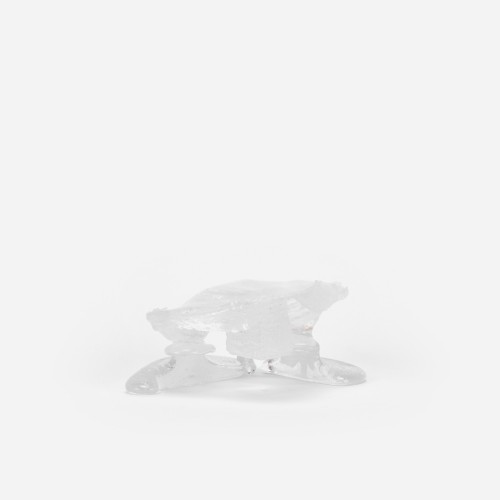

These test is an example of a glass piece casted into a ceramic fiber rope mould.

The ropes, woven together into a three-dimensional structure, created a temporary mould able to hold the molten glass, and conferred a particular texture to the surface of the piece.

Workshop

Mould Machine

Tutor

Augustin Scott de Martinville

Designer

Caroline Thurner

Hansel Schloupt

Process

Kiln casting