D008

Details

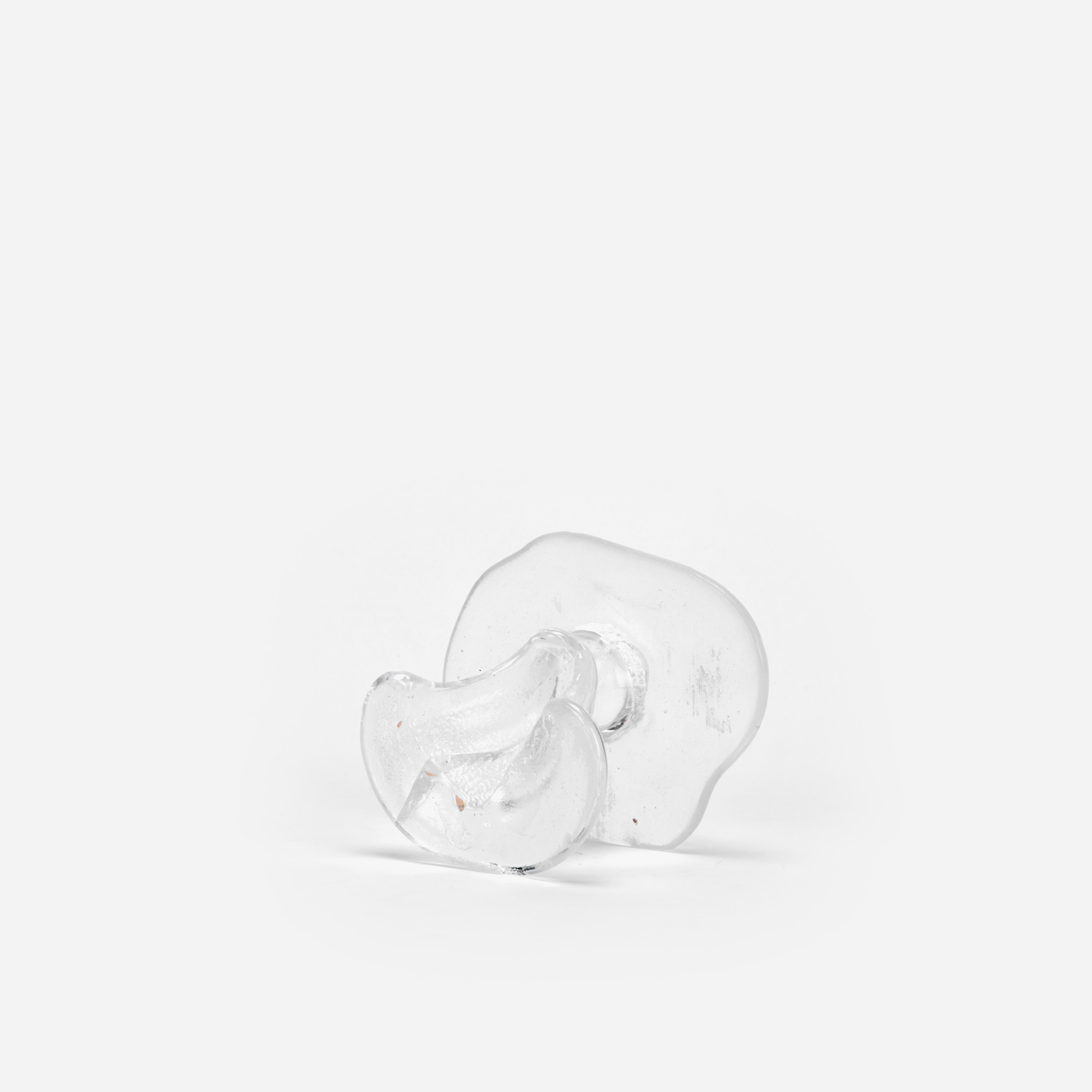

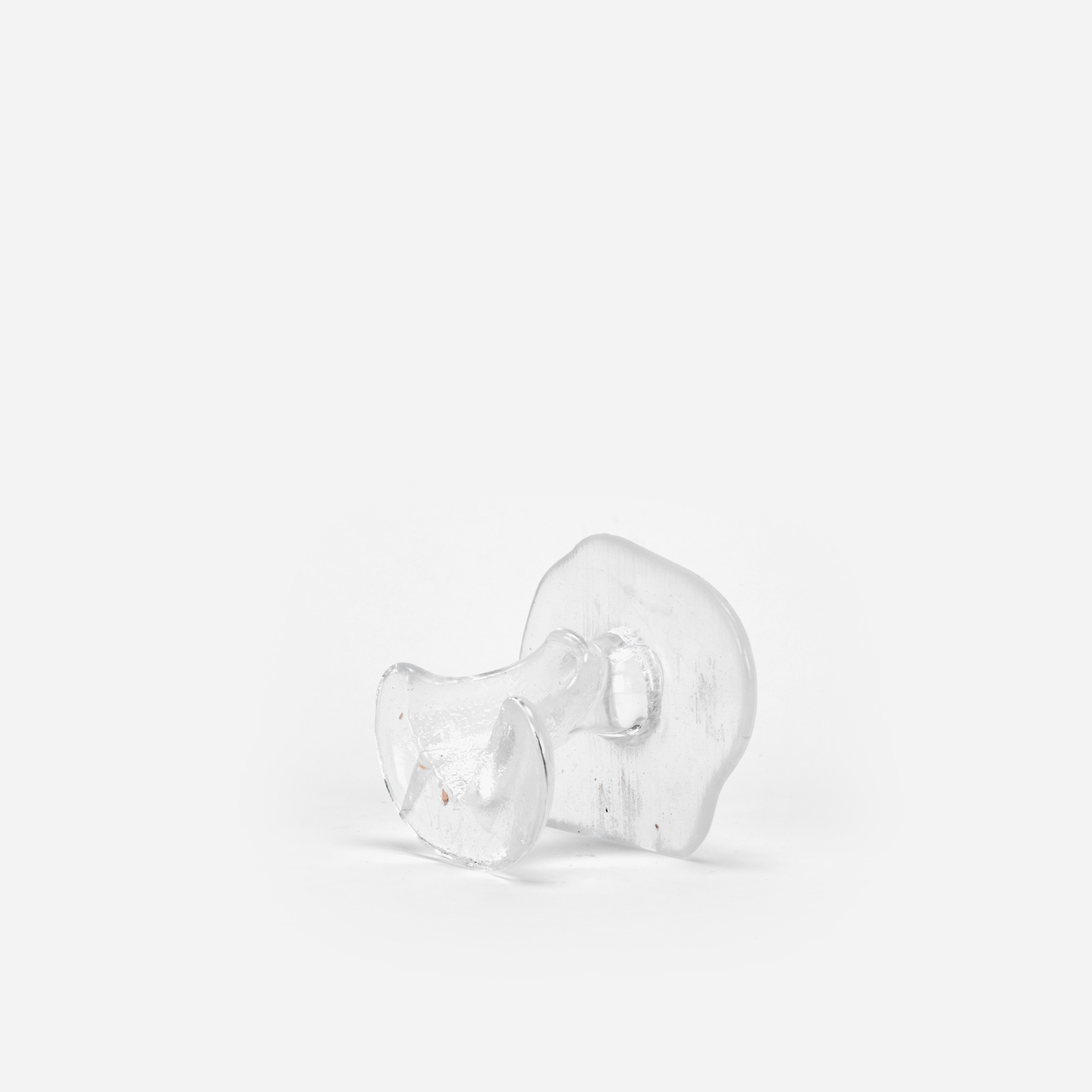

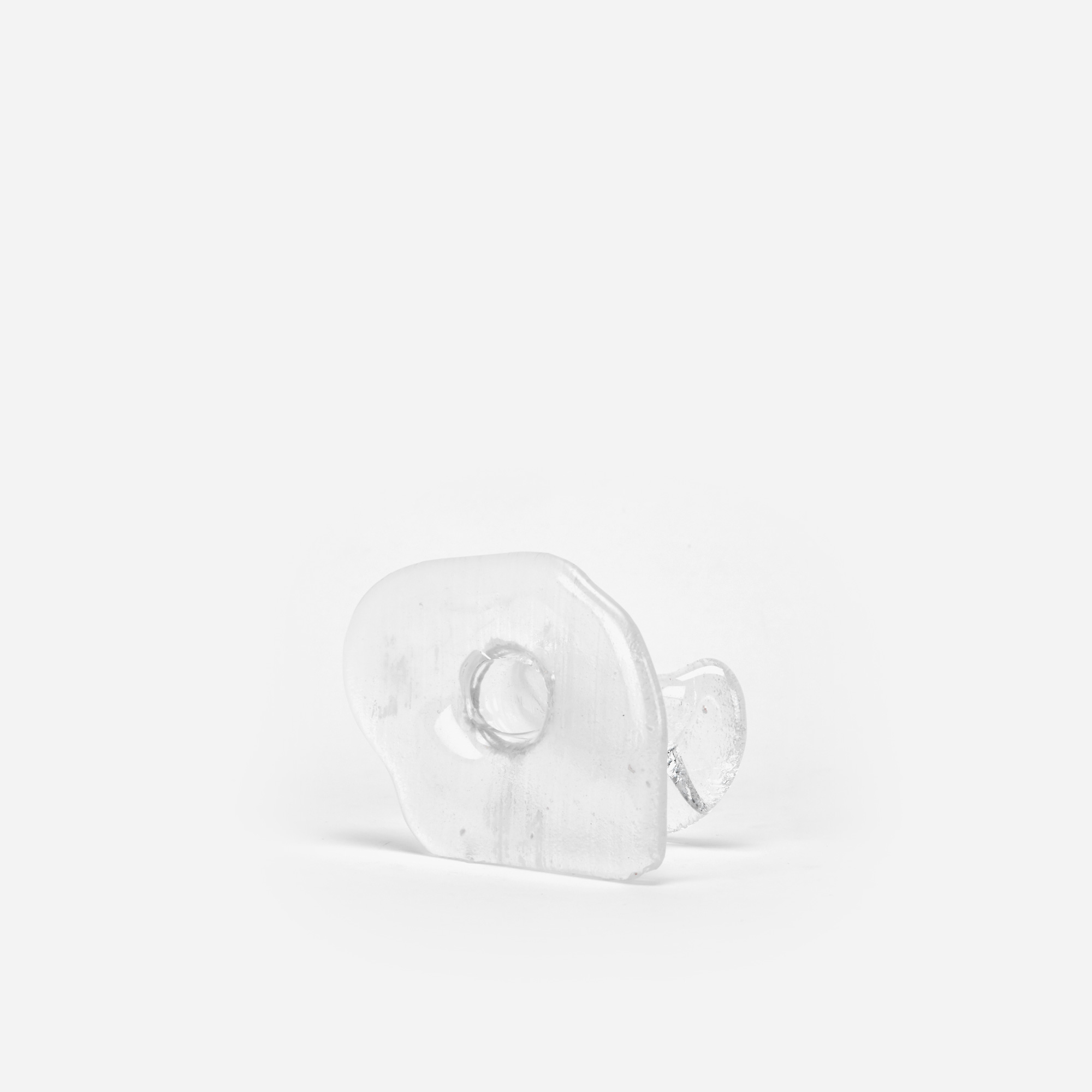

Kiln casting is a technique which requires a lot of precision in calculating the correct parabola of time and temperature to melt the glass and cool it down without cracks. At a certain heat threshold, the glass chips start to melt and flow from the crucibles into the moulds. This project attempted to “freeze” this phenomenon, letting the glass create a three dimensional shape through its own flowing.

This test represents the portion of glass which harden on top of the crucible and the amount of glass that managed to flow through during the firing.

A lot of effort has been spent on understanding the correct aperture and inclination of the funnel in order to let the glass slide with the correct speed.

Workshop

Mould Machine

Tutor

Augustin Scott de Martinville

Designer

Dong In Seol

Lucas Frank

Process

Kiln casting